Application field

Engineering machinery field: In engineering machinery, many parts need to have good wear resistance, such as loader buckets, bulldozer bulldozers, excavator arms and bucket teeth, etc. These parts are frequently in contact with abrasives such as soil and sand and gravel during work, and are prone to wear. Using wear-resistant steel plates to manufacture these parts can greatly increase their service life, reduce the number of repairs and replacements, and reduce the operating cost of equipment.

For example, after the loader bucket is made of wear-resistant steel plates, its service life can be increased by 2-3 times compared with the bucket made of ordinary steel plates.

Mining machinery field: The working environment of mining machinery is harsh, and materials such as ore and rock wear the equipment very seriously. Wear-resistant steel plates are required for the cylinder and lining of ball mills, hammers and jaw plates of crushers. The high strength and wear resistance of wear-resistant steel plates can ensure the normal operation of these equipment under high-speed operation and strong impact conditions.

For example, after the movable cone and fixed cone of the cone crusher are made of wear-resistant steel plates, their wear resistance is greatly improved, which can better crush hard ores and reduce the downtime and maintenance time of the equipment.

Construction industry: In the construction industry, wear-resistant steel plates are mainly used for some parts that are often subject to friction and impact, such as concrete mixing blades of construction machinery, paving machine ironing plates, etc. In addition, wear-resistant steel plates are also used in some building structures, such as expansion joints of bridges and exterior wall decorations of buildings, to prevent damage caused by long-term wind, sun and rain erosion.

For example, in large concrete mixing plants, after the mixing blades are made of wear-resistant steel plates, they can withstand the intense friction of aggregates in concrete, ensuring the mixing efficiency and the service life of the equipment.

Metallurgical industry: In the metallurgical production process, such as ironmaking and steelmaking, the transportation and processing of raw materials and products will cause serious wear and tear on the equipment. For example, the refractory linings of the blast furnace body and furnace waist need to be protected by wear-resistant steel plates. The high wear resistance and high temperature resistance of wear-resistant steel plates can ensure the normal operation of equipment in these high temperature environments and extend the service life of the equipment.

Product Parameters

| Product Name | Wear Resistant Plate |

| Standard | GB/T700 standard : Q235A,Q235B,Q235C,Q235D,Q235E |

| EN10025 standard : S235JR,S235J0,S235J2 | |

| DIN 17100 standard : St33,St37-2,Ust37-2,RSt37-2,St37-3 | |

| DIN 17102 standard : StE255,WstE255,TstE255,EstE255 | |

| ASTM standard : A36/A36M A36 | |

| A283/A283M A283 Grade A,A283 Grade B | |

| A283 Grade C,A283 Grade D | |

| A573/A573M A573 Grade 58, | |

| Grade 65,Grade 70 | |

| MOQ | 1 Ton |

| Technology | Hot roll, cold roll, cold drawn, ect. |

| Technique | Cold Rolled Hot Rolled |

| Model Number | Q235,Q345,Q405,40Cr,50Mn,65Mn,15CrMo,St37,St42 |

| Thickness | 1.2-2.0mm |

| Width | Customers’ Requirement |

| Length | Customers’ Requirement |

| Application | Interior and exterior decoration bridge construction |

| Loading Port | Tianjin/Qingdao/Shanghai Port |

| Price term | CIF FOB Ex-Work |

| Payment term | 30%T/T Advance + 70% Balance |

| Packing | Standard Sea-Worthy Package or as Required |

| Surface | Mild steel plain finish, hot dip galvanized, color coated, ect. |

| Size Tolerance | ±1%-3% |

| Processing method | Bending, Welding, Decoiling, Cutting, Punching, Polishing or as customer’s request |

| Size | Thickness from 0.1mm-5000mm, width from 0.5mm-5m, length from 1m-12m or |

| according to customer’s special request | |

| Weight Calculation | Weight(kg)=Thickness(mm)*Width(m)*Length(m)*Density(7.85g/cm3) |

| Trade Term | FOB,CIF,CFR,EXW,etc. |

| Price Term | T/T,L/C,Western Union,Paypal,Apple Pay,Google Pay,D/A,D/P,MoneyGram |

Product Specifications

| Specifications(mm) | Thickness(mm) | Specifications(mm) | Thickness(mm) |

| 1260*2440 | 1.5 | 1260*6000 | 4. 5 |

| 1260*2440 | 2. 0 | 1260*6000 | 4. 75 |

| 1260*6000 | 1.8 | 1260*6000 | 4. 95 |

| 1260*6000 | 2. 0 | 1260*6000 | 5. 5 |

| 1260*6000 | 2. 5 | 1260*6000 | 5. 75 |

| 1260*6000 | 2. 75 | 1260*6000 | 5. 75 |

| 1260*6000 | 2. 95 | 1510*6000 | 8. 0 |

| 1260*6000 | 3. 5 | 1510*6000 | 10 |

| 1260*6000 | 3. 75 | 1510*6000 | 12 |

| 1260*6000 | 3. 95 | 1510*6000 | 15 |

The above are the general items, for the special types, we can also meet your needs.

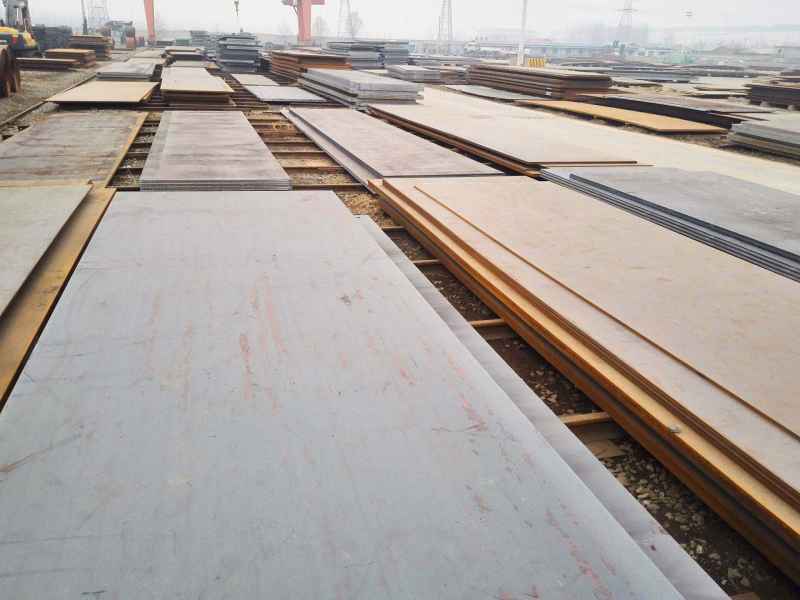

| Product Details | Product Production | Product Warehouse |

|

|

|

|

|

|

Applications

Wear-resistant plates are widely used in many industrial fields, such as mining, metallurgy, construction, chemical industry, etc. They can be used to make linings for conveying systems, such as conveyor drums, hoppers, storage silos, etc.; they can also be used to make linings for ore processing equipment, such as crushers, screens, etc.; and they can also be used for concrete mixers. , grinding machines, coal mining equipment, etc.

Project Cases

Additional Processing Technology

Wear resistant plates can be treated with additional processes such as cutting, welding, drilling, labeling, oiling, and beveling.

Product Packaging

Product Transportation