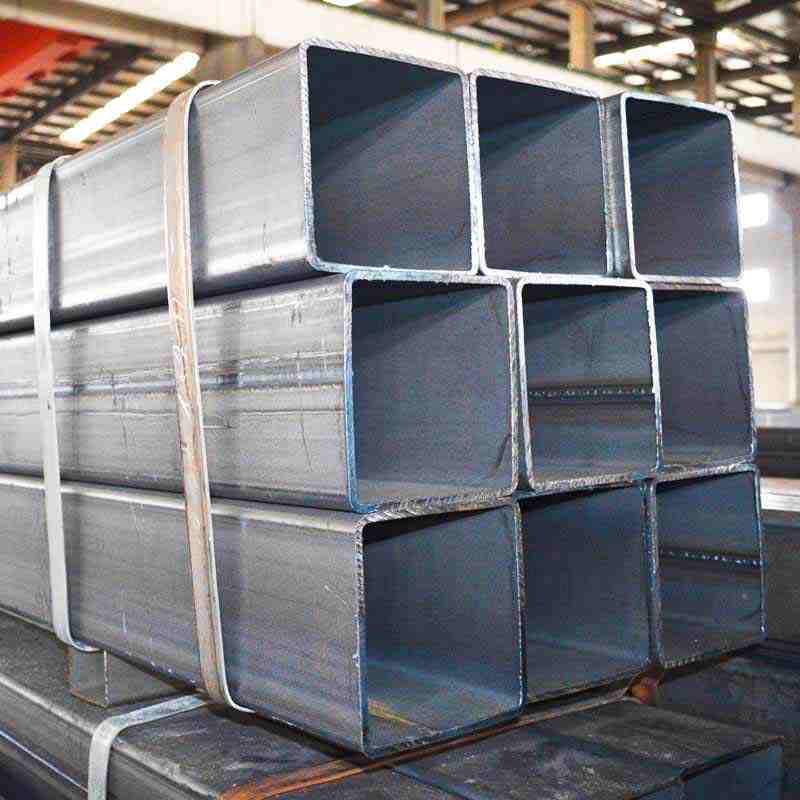

Carbon steel square tubes are widely used in construction, machinery, furniture, automobile and other industries due to their high strength, good corrosion resistance and welding performance.

Product Parameters

| Product Name | Carbon steel square tube | |

| Standard | ASTM: A105, A106, A106B, A106C, A178, A179, A192, A210, A519, A53, A53A, A53B,API5L,etc | |

| ASME: B36.19, B36.10,etc | ||

| SAE1018, SAE1020, SAE1045,etc | ||

| JIS: S20C, S25C, S35C, S45C, S55C,etc | ||

| DIN: C35, CK35, C45, CK45, etc | ||

| GB/T: 10#, 20#, 35#, 45#, 55#, etc | ||

| Material | 16Mn, 50Mn, 20Cr, 40Cr, 15CrMo, 20CrMo, 30CrMo, 35CrMo, 42CrMo, SS400,etc | |

| C35/CK35, C45/CK45, etc | ||

| SAE1018, SAE1020, SAE1045,etc | ||

| St37, St52, etc | ||

| Q195, Q215, Q235, Q275,Q295,Q345,Q355,Q390,etc | ||

| S235(JR,J0,J2),S275(JR,J0,J2),S355(JR,J0,J2),S420(N,ML),S460(M,ML) | ||

| Square Pipe Size | 16×16×0.4~1.5 ; 18×18×0.4~1.5 ; 20×20×0.4~1.5 ; 25×25×0.6~2.0 ; 30×30×0.6~4.0 ; 34×34×1.0~2.0 ; 35×35×1.0~4.0 ; 38×38×1.0~4.0 ; 40×40×1.0~4.5 ; 44×44×1.0~4.5 ; 45×45×1.0~5.0 ; 50×50×1.0~5.0 ; 60×60×1.5~5.0 ; 70×70×2.0~6.0 ; 75×75×2.0~6.0 ; 80×80×2.0~6.0 ; 85×85×2.0~6.0 ; 95×95×2.0~8.0 ; 100×100×2.0~8.0 ; 120×120×4.0~8.0 ; 150×150×6.0~10.0 ; 180×180×6.0~12.0 ; 200×200×6.0~30.0 ; 220×220×6.0~30.0 ; 250×250×6.0~30.0 ; 280×280×6.0~30.0 ; 300×300×8.0~30.0 ; 320×320×8.0~30.0 ; 350×350×8.0~30.0 ; 380×380×8.0~30.0 ; 400×400×8.0~30.0 ; 420×420×10.0~30.0 ; 450×450×10.0~30.0 ; 480×480×10.0~30.0 ; 500×500×10.0~30.0 | |

| Rectangular Tube Size | 10×20×0.6~1.5 ; 14×21×0.6~1.5 ; 15×30×1.5~1.5 ; 15×38×0.6~1.5 ; 20×30×0.6~2.0 ; 20×40×0.8~2.0 ; 20×50×1.0~2.0 ; 22×35×0.9~2.0 ; 25×40×0.9~3.75 ; 25×65×1.0~2.0 ; 30×40×1.0~3.75 ; 30×45×1.0~3.75 ; 30×50×1.0~4.0 ; 30×60×1.0~4.5 ; 40×50×1.0~4.5 ; 40×60×1.0~5.0 ; 40×80×1.5~5.0 ; 40×100×2.0~5.0 ; 50×60×2.0~5.0 ; 50×80×2.0~5.0 ; 50×100×2.0~8.0 ; 60×80×2.0~6.0 ; 80×100×2.0~8.0 ; 120×60×2.5~10.0 ; 120×80×2.5~10.0 ; 150×100×2.5~12.0 ; 180×150×2.5~12.0 ; 200×100×4~12.0 ; 200×150×4~12.0 ; 250×150×6~12.0 ; 250×100×6~12.0 ; 250×200×6~30.0 ; 300×150×6~30.0 ; 300×200×6~30.0 ; 300×250×6~30.0 ; 400×250×8~30.0 ; 400×300×8~30.0 ; 450×200×8~30.0 ; 450×250×8~30.0 ; 400×300×8~30.0 ; 400×350×8~30.0 ; 500×200×10~30.0 ; 500×250×10~30.0 ; 500×300×10~30.0 ; 500×350×10~30.0 ; 500×400×10~30.0 ; 500×450×10~30.0 | |

| Surface | Galvanized, PVC, Black-Painting, Color-Painting, Transparent-Oil, Anti-Rust-Oil, Black-Varnish, 2PE, 3PE, Epoxy-Coating, BE, PE | |

| Technique | Hot Rolled, Cold Drawn, Forging, Seamless or Welded | |

| Pipe Ends | 1) Plain 2) Beveled 3) Threaded with coupling and plastic cap | |

| Deep Processing | Oiled, Painted, Galvanized, Powder Coating, Shrink Head, Pressure Groove, Welding Head, Punching, Threaded With Coupling and Plastic Cap | |

| Package | Bundles, Bulk,sea worthy wooden case packing or pr your requirement | |

| Inspection | With Hydraulic Testing, Ultrasonic testing or X-ray Test | |

| Date of Delivery | Less Than 7/15/20/25/30/40/50/60 Days According To The Quantity | |

| Package | Standard sea-worthy package or as required | |

| Seaworthy packing | 20ft GP: 5.8m(length) x 2.13m(width) x 2.18m(high) ;about 24-26CBM | |

| 40ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) ;about 54CBM | ||

| 40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high) ;about 68CBM | ||

Product Specifications

| Specifications(mm) | |||

| 20*20*1.0 | 80*80*3.5 | 30*30*2.5 | 150*150*3.75 |

| 25*25*1.8 | 80*80*7.75 | 30*30*2.75 | 150*150*5.75 |

| 25*25*2 | 100*100*11.75 | 40*40*1.5 | 180*180*8 |

| 25*25*2.5 | 100*100*2.75 | 40*40*2.5 | 200*200*4.75 |

| 25*25*2.75 | 100*100*3.75 | 50*50*2.5 | 200*200*7.5 |

| 250*250*9.5 | 100*100*4.75 | 50*50*2.5 | 200*200*7.75 |

| 30*30*0.7 | 100*100*7.75 | 50*50*3.0 | 300*300*11.75 |

| 30*30*1.5 | 120*120*2.75 | 50*50*3.5 | 300*300*12 |

| 30*30*1.8 | 120*120*4.75 | 50*50*3.5 | 300*300*9.75 |

| 30*30*2 | 150*150*11.75 | 60*60*2.5 | 400*400*11.5 |

| 80*80*2.5 | 500*500*11.75 | 60*60*3.0 | 400*400*11.75 |

| The above are the general items, for the special types, we can also meet your needs. | |||

| Product Details | Product Production | Product Warehouse |

|

|

|

|

|

|

Applications

Carbon steel pipes are used in the construction industry, oil and gas industry, manufacturing, chemical industry, metallurgy, electric power, environmental protection and other fields. They are widely used in manufacturing structural parts and mechanical parts, such as oil drill pipes, automobile drive shafts, bicycle frames and construction Steel scaffolding used in construction, etc.

Project Cases

Additional Processing Technology

Carbon steel pipes can be treated with additional processes such as cutting, punching, labeling, oiling, welding, bending, and beveling.

Product Packaging

Product Transportation